Mic 6 tooling plate

Re: Mic 6 tooling plate

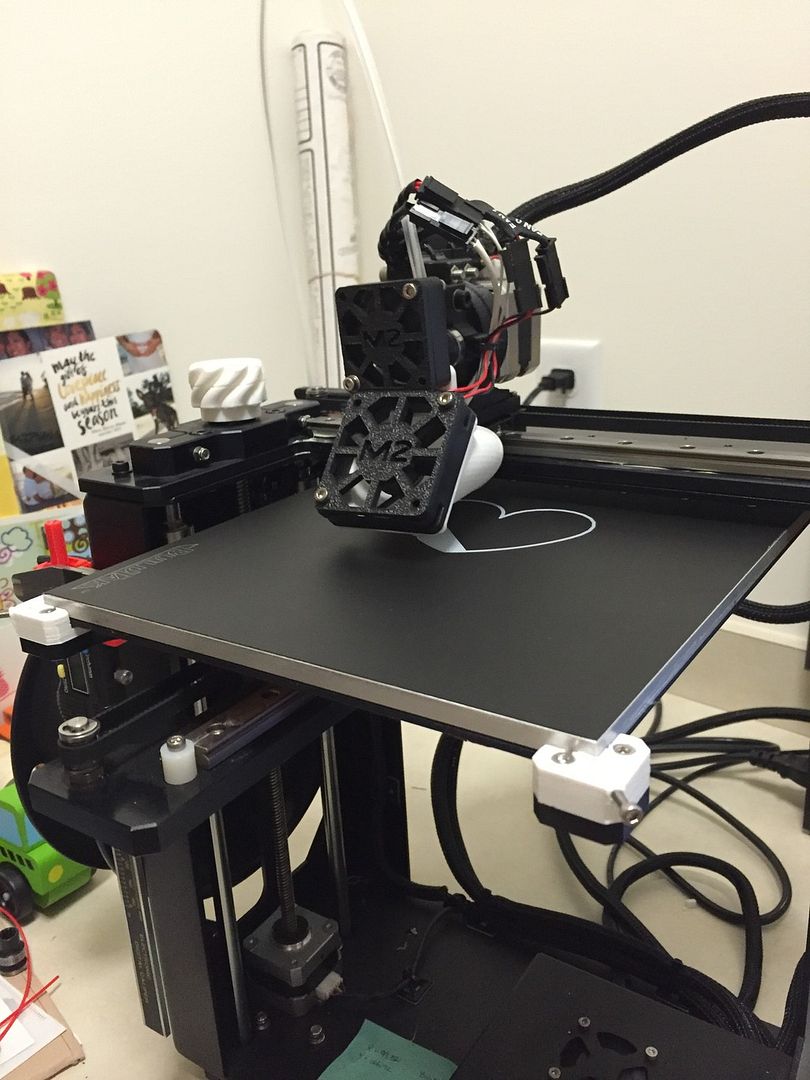

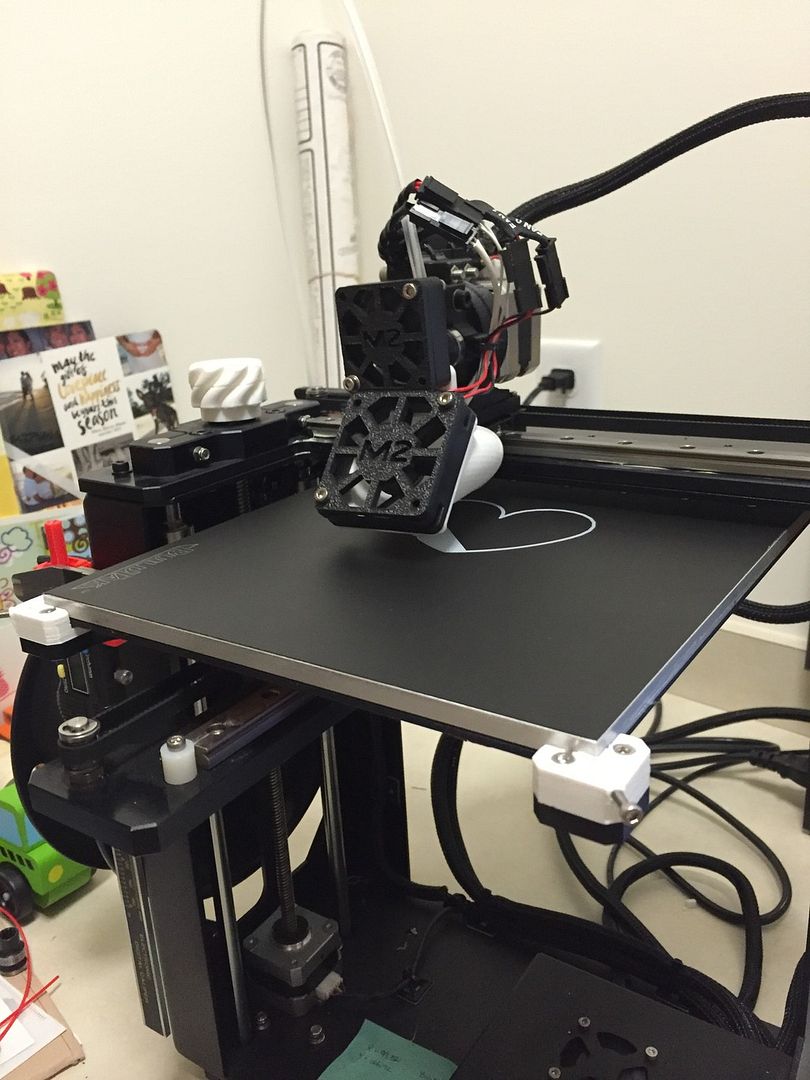

I got my plate today!

MANY Thanks to jimc for making it for me and sending it all the way to Europe!

Good timing as I got fed up about the core heatbed on my M2 being slightly buckled up in the middle, and this has caused the nozzle to scrape my print surface (BuildTak) slightly when it sticks around the corners.

Nothing more of that now, thankfully!

Now, just to finish the things I need to get the bed tramming work, then I'll be happy!

MANY Thanks to jimc for making it for me and sending it all the way to Europe!

Good timing as I got fed up about the core heatbed on my M2 being slightly buckled up in the middle, and this has caused the nozzle to scrape my print surface (BuildTak) slightly when it sticks around the corners.

Nothing more of that now, thankfully!

Now, just to finish the things I need to get the bed tramming work, then I'll be happy!

Re: Mic 6 tooling plate

I do not yet have an M2, but do have a TinyBoy which so far has worked quite well with PLA and the small things which fit in its envelope of 80x76x80. I hope it is not outrageous for me to ask a question here which does not directly apply to M2's.

I, too, would like a Mic 6 bed, but 1/4 inch thickness might be too heavy for what is basicly a lightweight perspex frame machine. The bed would need to be about 4 inch square and 1/8 inch thick would make its weight close enough to the present perspex bed. Can I get a 1/4 inch plate of mic 6, get one face bead blasted and then mill down the back until its .125? Would reducing the thickness of one of these plates by 50% destroy its thermal stability?

BTW, if anyone thinks I shouldn't post something like this here, say so. SWBO would never let me spend $1.8k unless I knew for sure it would work for me. Maybe this winter, especially if the kits come back.

john

I, too, would like a Mic 6 bed, but 1/4 inch thickness might be too heavy for what is basicly a lightweight perspex frame machine. The bed would need to be about 4 inch square and 1/8 inch thick would make its weight close enough to the present perspex bed. Can I get a 1/4 inch plate of mic 6, get one face bead blasted and then mill down the back until its .125? Would reducing the thickness of one of these plates by 50% destroy its thermal stability?

BTW, if anyone thinks I shouldn't post something like this here, say so. SWBO would never let me spend $1.8k unless I knew for sure it would work for me. Maybe this winter, especially if the kits come back.

john

Re: Mic 6 tooling plate

A 4x4 plate would be pretty lightweight at 1/4". I have no idea how it would react at 1/8"

Re: Mic 6 tooling plate

Mic 6 is not made at 1/8" nor 3/16" at least the company that copyright it say from 6mm-100mm or 1/4"-4"

https://www.alcoa.com/mill_products/catalog/mic-6.pdf

I am heard someone saying he was selling 1/8" but i doubt it will retain the same physical characteristic by the book 1/4" is the minimum for an official Mic 6

honestly if ur bed is not heated there are other aluminium that go easily to 3/18 T6016

https://www.onlinemetals.com/merchant.c ... top_cat=60

as you can see this one has many more thickness then this one

https://www.onlinemetals.com/merchant.c ... top_cat=60

if is for a toy-ish machine maybe the T6016 0.16" is enough they have 0.19" too

https://www.alcoa.com/mill_products/catalog/mic-6.pdf

I am heard someone saying he was selling 1/8" but i doubt it will retain the same physical characteristic by the book 1/4" is the minimum for an official Mic 6

honestly if ur bed is not heated there are other aluminium that go easily to 3/18 T6016

https://www.onlinemetals.com/merchant.c ... top_cat=60

as you can see this one has many more thickness then this one

https://www.onlinemetals.com/merchant.c ... top_cat=60

if is for a toy-ish machine maybe the T6016 0.16" is enough they have 0.19" too

Re: Mic 6 tooling plate

Given that the plate starts with a flatness spec of 0.015 inch = 0.38 mm, you'd want to not wreck the main reason everybody loves them: their flatness. The plate wouldn't curl up like a potato chip, but make sure the mill is trammed and aligned properly.jferguson wrote:then mill down the back until its .125?

For whatever it's worth, I stacked a pair of 100x120x3 mm (call it 1/8 inch) aluminum sheets on a plywood-and-plastic Thing-O-Matic with good results: the bottom sheet contacted the PCB-style heater and the top sheet removed easily.

http://softsolder.com/2011/04/13/thing- ... ild-plate/

I'd see how the 1/4 inch plate works and mill it down only if it causes problems.

Re: Mic 6 tooling plate

trying the mic 6 at 1/4 inch and then doing the milling only if necessary - stepper load too high - makes a lot of sense. I suppose I could try a piece of 6061 t6 first, since I have some. i could get it bead-blasted in the next town. one thing does seem evident, though, in working with the tinyboy. A lot of problems that must be addressed in design and configurations are size or volume related and since this machine works on such small prints, it doesn't seem so sensitive.

thanks for your thoughts, guys,

john

thanks for your thoughts, guys,

john

Re: Mic 6 tooling plate

When you get the plate blasted be sure to tell them low pressure. It needs to be completely blasted but the profile must be very fine. When its all done rub it down with a red scotchbrite pad. In the end it should have a finish like frosted glass. Very smooth feeling. I blast all the ines i do for the guys here with a fine crushed recycled glass at 40psi.

- willnewton

- Posts: 479

- Joined: Wed Apr 09, 2014 8:32 pm

Re: Mic 6 tooling plate

Here is another source for MIC6. http://midwestmetalwarehouse.com/alumin ... plate.html

I needed to order a 19x25x3/8 sheet as a build plate for my MPCNC. This company provides custom cuts and prices were not far off the stock size prices from other suppliers and improved over several I looked at.

The BIG difference is what happens to the pricing once you go for a custom size. You can get a custom cut without an insane markup. I bet they cut most stuff as it is ordered, so to them everything is a custom cut. With other places I have found that once you get outside of their stock items, things get expensive fast.

Some pricing may be listed lower than other sites as well, but they charge a "processing/cut fee" which brings the price up, but still in line with other websites "stock size" pricing.

Shipping fees were reasonable as well and I received several emails keeping me up to date on the progress of the order. The plate arrived via UPS with a small ding on one edge that was caused in transit, but it was a non-issue. The plate was wrapped in official Alcoa MIC6 protective plastic, so it's legit.

I would consider ordering from them again. If I needed a custom piece of MIC6 I will absolutely order from there again.

I needed to order a 19x25x3/8 sheet as a build plate for my MPCNC. This company provides custom cuts and prices were not far off the stock size prices from other suppliers and improved over several I looked at.

The BIG difference is what happens to the pricing once you go for a custom size. You can get a custom cut without an insane markup. I bet they cut most stuff as it is ordered, so to them everything is a custom cut. With other places I have found that once you get outside of their stock items, things get expensive fast.

Some pricing may be listed lower than other sites as well, but they charge a "processing/cut fee" which brings the price up, but still in line with other websites "stock size" pricing.

Shipping fees were reasonable as well and I received several emails keeping me up to date on the progress of the order. The plate arrived via UPS with a small ding on one edge that was caused in transit, but it was a non-issue. The plate was wrapped in official Alcoa MIC6 protective plastic, so it's legit.

I would consider ordering from them again. If I needed a custom piece of MIC6 I will absolutely order from there again.

I'm finally back to where I started two days ago!

A thread with some stuff in it I update every once in a while. viewtopic.php?f=8&t=9

See some of my stuff http://www.thingiverse.com/willnewton/favorites

A thread with some stuff in it I update every once in a while. viewtopic.php?f=8&t=9

See some of my stuff http://www.thingiverse.com/willnewton/favorites

Re: Mic 6 tooling plate

Just got my mic6 plate in today. Had a shop machine the perimeter, so it sits nicely on the heating plate.

I had a spare buildtak sheet, so I stuck it on and couldn't have been happier.

I was suffering from a glass plate tolerance issue, and the mic6 solved that immediately. I now can print almost edge to edge with no issues. I FINALLY can walk away during printing and not worry about first layer issues.

I am certainly not a pro like many of you on the forums, but the mic6 got me back to printing again.

I bought from onlinemetals.com and the shipping to hawaii was $6!! I just got a 20% off code if you guys wanna use it. Code expires Tuesday 2/16/16. The code is DCB6A. I ordered a custom size (7.95" x 9.95"), and my total was $38.00. With this coupon, the total was approx. $31.00

Hope this helps some guys who were on the fence about buying a mic6 plate.

Thanks,

I had a spare buildtak sheet, so I stuck it on and couldn't have been happier.

I was suffering from a glass plate tolerance issue, and the mic6 solved that immediately. I now can print almost edge to edge with no issues. I FINALLY can walk away during printing and not worry about first layer issues.

I am certainly not a pro like many of you on the forums, but the mic6 got me back to printing again.

I bought from onlinemetals.com and the shipping to hawaii was $6!! I just got a 20% off code if you guys wanna use it. Code expires Tuesday 2/16/16. The code is DCB6A. I ordered a custom size (7.95" x 9.95"), and my total was $38.00. With this coupon, the total was approx. $31.00

Hope this helps some guys who were on the fence about buying a mic6 plate.

Thanks,

Re: Mic 6 tooling plate

That's frankly an amazing price and I don't care if it's a spam post or not (doubtful) I'm approving it. Anybody who was on the fence about the MIC6 plate should get one at that price.

Custom 3D printing for you or your business -- quote [at] pingring.org