rpollack wrote:fastening a card edge connector to the bottom rear edge of the HBP.

The flying cable from chassis to HBP must have strain relief on the outboard side of the new connector, which I think puts

way too much stress on the back end of the spring-supported HBP: dynamic forces applied to the the HBP change the platform Z position as a function of travel along the Y axis. Those platform springs are the weakest point of the whole design.

I'd much rather see a pigtail from the HBP to a connector mounted firmly on the Y-axis slide (below the springs), so that the pigtail doesn't move in relation to the HBP. Then you can do a good job of strain relief on the flying cable-to-connector joint, without affecting the HBP.

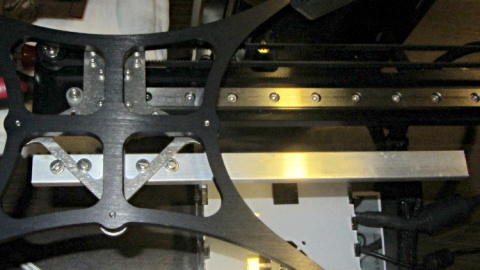

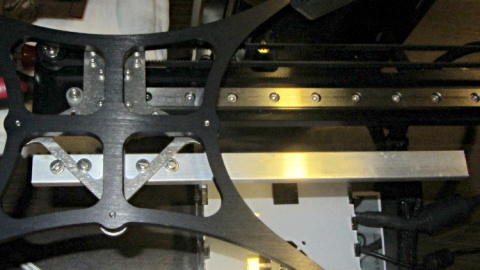

I ran a strut out the back of the Y-axis stage in a truly hideous hack:

http://softsolder.com/2013/07/05/makerg ... ilization/

Then lashed the HBP cable to that strut:

That's not as good as a pigtail with a firmly mounted connector, but it was a start.

I've since switched to a different HBP with longer wires running directly to the chassis that reduce the acute bending. It's not nearly as good-looking as the loom, though.

A pair of Anderson Powerpoles would be a

much more reliable choice than any PCB edge connector, because the copper PCB traces will fret against the contacts after repeated mechanical motion. If you must clamp the connector together anyway, you may as well use a high-current latching connector and be done with it.

PCB-mount Powerpoles exist:

http://www.andersonpower.com/products/p ... rpole.html

But that PCB should be attached to the Y-axis slide, so it's not clear they're an advantage over ordinary Powerpoles on a pigtail.