When is a dual extruder/supports required?

Posted: Sat Jun 25, 2016 11:00 pm

I'm trying to choose a 3D printer for small production runs of electronic enclosures, sorta bridging the gap before injection molding. I really like the looks of the M2 but trying to understand if it's going to be good enough.

Support material needed?

When do I need to start printing support material? What kind of overhang length and angle can be reliably high quality printed with a single extruder? My designs really only have rounded corners about 3mm radius or less on a 1.5mm thick wall. Would that print well without support? I've attached a couple STLs if that helps. Does anyone think I'd need the dual upgrade to print these well?

What does 10micron x-y precision mean?

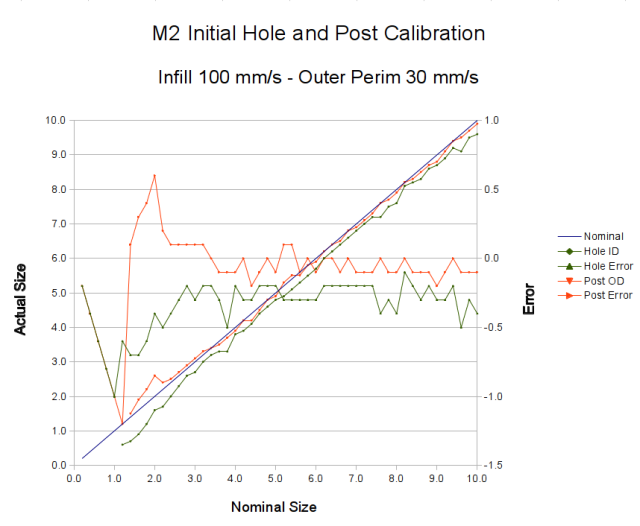

I'm also having trouble grasping the precision specs. If x-y precision is .01mm, does that mean my circular button holes in the x-y plane will be circular to within .01mm with centers accurate to .01mm? Or does nozzle size affect that? 10 microns seems pretty amazing, I'd be happy if 50 microns was reliable.

Is it really this cheap?

And a final consideration for me is total part cost. It seems very low by my calculation, I'm worried I'm missing something. Can someone correct me? or add a hidden cost I'm not aware of?

PLA = $35/1kG

Density of PLA = 1.24g/cc

My model volume: 10cc

= $0.42 per model

That's cheaper than an injection mold run of 500 parts in a single cavity. Are there any other consumable parts I don't know about? Can I expect my M2 to run 24/7 for 6 months without major expenses?

Thanks so much for your help guys! Look forward to joining you if this proves as good as it sounds.

Support material needed?

When do I need to start printing support material? What kind of overhang length and angle can be reliably high quality printed with a single extruder? My designs really only have rounded corners about 3mm radius or less on a 1.5mm thick wall. Would that print well without support? I've attached a couple STLs if that helps. Does anyone think I'd need the dual upgrade to print these well?

What does 10micron x-y precision mean?

I'm also having trouble grasping the precision specs. If x-y precision is .01mm, does that mean my circular button holes in the x-y plane will be circular to within .01mm with centers accurate to .01mm? Or does nozzle size affect that? 10 microns seems pretty amazing, I'd be happy if 50 microns was reliable.

Is it really this cheap?

And a final consideration for me is total part cost. It seems very low by my calculation, I'm worried I'm missing something. Can someone correct me? or add a hidden cost I'm not aware of?

PLA = $35/1kG

Density of PLA = 1.24g/cc

My model volume: 10cc

= $0.42 per model

That's cheaper than an injection mold run of 500 parts in a single cavity. Are there any other consumable parts I don't know about? Can I expect my M2 to run 24/7 for 6 months without major expenses?

Thanks so much for your help guys! Look forward to joining you if this proves as good as it sounds.