Page 1 of 1

Print Size Expectations

Posted: Fri Nov 14, 2014 7:25 pm

by Windcharger

I'm 99% sure on getting the M2 after researching the other printers out there. This will be my first printer so I have no experience in what to expect printing small. In particular printing a small ball joint which would have a simple design of a sphere attached to a cylinder. Now using the .35mm nozzle and having the printer and STL file in a theoretical perfect tuned state, what would be a realistic expectation printing with the sphere being 5MM? possible to go down to 3MM? what about PLA verse ABS. I've been learning OpenScad and while I can have the variables easily adjusted in the code, I'm always thinking about whats realistic without actually having a printer yet and knowing some limitations. Thanks

Re: Print Size Expectations

Posted: Fri Nov 14, 2014 7:43 pm

by insta

The biggest issue with printing small is heat, which is closely followed by ooze. If you print a single one of those parts, the hot nozzle moving around in approximately the same place will cause some hellacious blobbing and turn the part into an unrecognizable mess. You can easily remedy this by printing several at once, so when the print head moves to the next one in line, the layer on the first one can cool down.

A printed joint that small won't be very strong though, certainly not as sturdy as a machined one of the same dimensions.

Our feature size can reliably go down to 0.1mm in the Z axis, and about 0.5mm in X/Y. The nozzle itself is smaller, and we can make smaller "dots", but they're not terribly precise anymore.

Re: Print Size Expectations

Posted: Fri Nov 14, 2014 8:07 pm

by Windcharger

Perfect, Thank You insta! My application would be for some functional toy like objects. I reckon its do able, and as I suspected it would just be a mater of some trial and error for a particular scenario on what the trade off is on minimum size and strength.

Re: Print Size Expectations

Posted: Fri Nov 14, 2014 9:27 pm

by insta

MakerGear sells a 0.25mm nozzle as well, if you want to get particularly aggressive with small prints.

Re: Print Size Expectations

Posted: Fri Nov 14, 2014 10:26 pm

by jsc

Here's an example of a small cylinder. The train is a Chinese knockoff of one of the Thomas train engines that had a smokestack knocked off. The printed replacement is the one on the right. I forget the exact size, but it's probably something like 5mm in diameter. Printed it as a single, so there are no issues with cooling in PLA if you print slow enough.

What will give you some problems are spheres. The bottoms are unsupported, so it is difficult to print them at high quality in one go, and the smaller you go the more pronounced any defects are relative to the size of the object. If you are planning to use them as bearings, I would just design around a real ball bearing.

Re: Print Size Expectations

Posted: Sat Nov 15, 2014 3:23 am

by ednisley

Windcharger wrote:printing with the sphere being 5MM? possible to go down to 3MM?

You'll run into several problems that make small spheres pretty much un-do-able on any 3D printer that's extruding plastic filament; they're not unique to the M2.

The layer height determines how accurate the sphere can be. A 5.0 mm sphere will have only 25 layers at 0.20 mm/layer, which will be rather gritty. Depending on how the slicer arranges things, the top layer three layers will be disks with diameters = 2 mm, 2.7 mm, and 3.2 mm, which won't look much like a sphere. You can improve that by running 0.1 mm layers, but then the molten plastic's viscosity starts to matter.

The perimeter of each layer will suffer from small irregularities: retraction zits, bulges and dents from the infill pattern, and suchlike. On a good day with a tailwind, the position will vary ±0.1 mm from nominal, so call it 2% of the diameter at the equator and far more at the poles.

The cylinder supporting the sphere should be at least D/sqrt(2) in diameter, so that the unsupported part of the sphere starts at a 45° angle. For a 5 mm sphere, the cylinder will be 3.5 mm diameter. You can fiddle with that a bit, trading off diameter with droop, but the cylinder must remain rather chunky and will limit the socket's tilt angle around the ball.

Given enough stress, extruded plastic will separate between the layers, so the cylinder + sphere will be weakest perpendicular to the cylinder's axis: it's not going to withstand much lateral force from the ball. Skinny cylinders aren't very strong and, if you're trying to print it as a tall stalk stuck to the platform, you'll have adhesion problems.

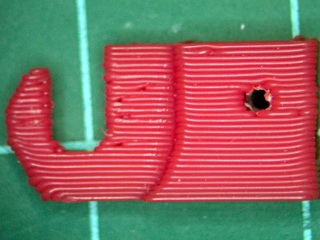

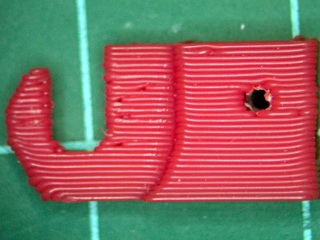

This digital caliper repair part has 0.33 mm thread thickness and 0.66 mm width:

The top view shows how the fill fits into the rectangular outline:

My old Thing-O-Matic produced that, back in the day, and I was delighted:

http://softsolder.com/2011/05/27/thing- ... erfection/

All in all, I think you'll be unhappy with tiny 3D printed balls, no matter which 3D printer you get. Perhaps an optical printer that congeals objects from photopolymer would be better, although I think those run in a different price league.

Hope that helps define some of the parameters...

Re: Print Size Expectations

Posted: Tue Nov 18, 2014 1:35 am

by Windcharger

Thank you all for the insight to this!. One thing for sure is that if I go with the M2 I feel totally confident ya'll would be there for support to a newbie

Re: Print Size Expectations

Posted: Fri Nov 21, 2014 3:38 am

by Windcharger

I've done some further research on this and came across this site

http://www.instructables.com/id/Micro-3 ... l/?lang=pt I'm sure the pieces aren't that strong but the round spheres on the pawn pieces don't look too bad, If I could get results like that I'd be satisfied. I can't see the Replicator 2 having that much of a difference verse M2 in getting the results that were shown.

Re: Print Size Expectations

Posted: Fri Nov 21, 2014 4:01 pm

by ednisley

That's at 0.1 mm layer thickness. Note the layers on the top of the knight in the "Passo 4" section: that's the resolution limit staring you in the face.

The ball on the pawn looks to be about 5 mm diameter and has 50 layers, twice that of the 0.2 mm in my examples; the top disks will be 1.40, 1.96, and 2.37 mm diameter. The fine layers make the equator look great, though!

One thing you

won't have trouble with on your MakerGear M2:

The more pieces you print at a time, the more the play in the guide rails becomes apparent. The creeping error in mechanical inaccuracies results in less detail and blobby artifacts.

The notion of printing a negative mold, then casting the positive piece in another material may be useful: you can apply a fine finish inside the mold that you can't do directly on the positive.

Re: Print Size Expectations

Posted: Fri Nov 21, 2014 5:16 pm

by insta

With parts this small, I think the general thing will be "wow the printer actually did it" instead of "why won't the printer do it?". You're at the limits of what's practical with FDM technology, so don't expect to unbox the machine and immediately pop out those tiny prints.