wisdomknight wrote:I thought the M2 would print at 25um out of the box.

And, indeed, it can. You probably don't want to do that, because it won't produce noticeably better print quality.

"Resolution" is one of the things that the tech press has

absolutely wrong about fused filament 3D printing: that's the absurdly small stepper motor resolution along the Z axis. What they don't mention is that the resolution in the XY plane is limited by the nozzle diameter and can't get better than about 0.3 mm.

As a result,

all 3D printer manufacturers bullet-list their Z-axis resolution, because it's the only number anybody knows about when they start evaluating printers.

Good manufacturers, like Makergear, also list the nozzle diameter, but nobody knows what that means: the press doesn't mention it.

So, yes, you can print 25 micron = 0.025 mm layers by specifying that in the slicer, then go crazy with first-layer adhesion problems, nozzle clogging, and excessive fussiness. Fine layers also increase the total print time: a one-hour print with 0.25 mm layers will require

ten hours with 0.025 mm layers.

Within each of those 25 µm layers, the printer still can't produce XY features smaller than about 0.8 mm on a side: a pair of 0.4 mm plastic threads laid down side-by-side. Depending on the model and the slicers, you

may be able to produce 0.40 mm single-thread features, but then you face problems with adhesion to the previous layer and the effect of retraction on tiny features.

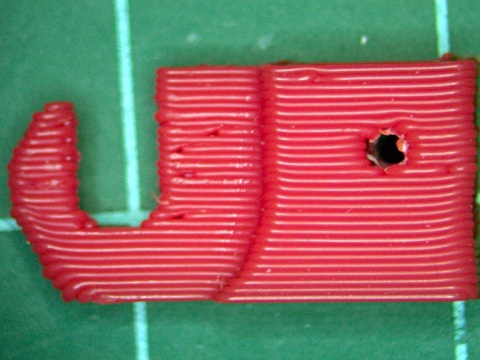

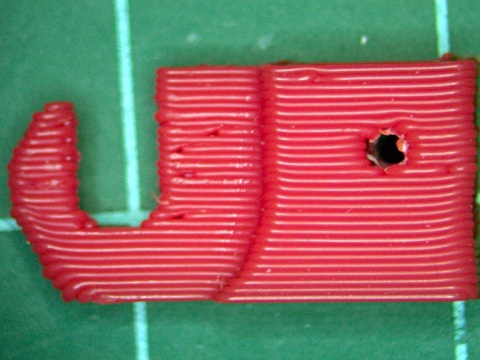

Here's a small repair part I made some years ago in ABS through a 0.50 mm nozzle, 0.33 mm layers, and 0.66 mm thread width on a much-improved Makerbot Thing-O-Matic:

https://softsolder.com/2011/05/27/thing ... erfection/

It's 20 mm long, 6 mm wide, and 10 mm tall. At the time, it was the smallest repair part I'd ever made.

The side view shows the layers:

My M2, pushing PETG through a 0.35 mm nozzle, produces 0.40 mm threads in 0.20 mm layers, which is what I've told Slic3r to do. Other folks around here have produced sub-0.10 mm layers, with about the same XY resolution.

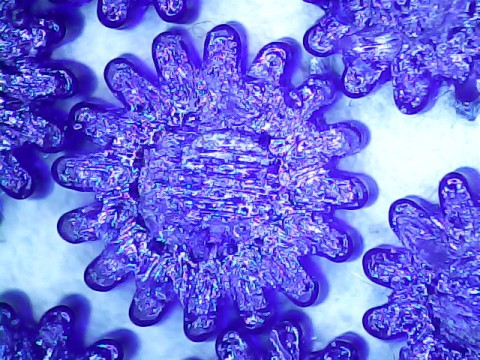

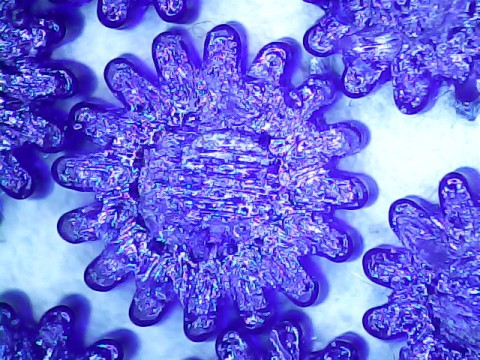

These support spiders held up a 6-32 nut recess:

https://softsolder.com/2016/02/10/vacuu ... e-sockets/

The big star in the middle measures a bit under 9 mm OD and the smaller stars are 7 mm, with teeth 1 mm across. You can just barely make out the two threads forming each tooth, with rounded ends because the nozzle can't produce square corners!

In round numbers, that's as good as it gets: the plastic can't get any smaller!