Page 1 of 3

How do you deal with the end of a filament roll?

Posted: Wed Jul 16, 2014 3:39 pm

by Merad

We've had our M2 long enough now that we'll soon be at the end of a few filament rolls... which makes me wonder how most people deal with this? Do you just eyeball the amount left to decide when to stop using it, and maybe hold the leftovers for small prints? Or is there some technique to splice together filament so you don't end up with waste at the end of a roll?

Re: How do you deal with the end of a filament roll?

Posted: Wed Jul 16, 2014 5:08 pm

by jsc

You can weigh your roll and subtract off the weight of an empty holder, then figure ~330m for 1 kg to approximate how many mm you have left. Your slicer should tell you how much filament a print is going to use.

I have been looking into filament splicing, but my ad hoc attempts have not come to much so far. I have heard that using a hot knife (used to cut nylon webbing) can work. Hm, maybe just licking the ends up against the outside of the extruder might work....

Re: How do you deal with the end of a filament roll?

Posted: Wed Jul 16, 2014 9:05 pm

by dryeti

I just watch the ongoing print when I think that I could reach the end of the roll. As soon as the end is near I pause the print, change rolls, and let the print continue. This way you don't have significant waste. I use RepetierHost for executing the g-code which automatically finds the previous position of the print head after the pause - I'm not sure whether simplify3d does the same.

Re: How do you deal with the end of a filament roll?

Posted: Thu Jul 17, 2014 3:38 pm

by ebmonon36

I do more of a "hot swap" method. When I am getting close to the end of a roll, I watch the print. When the last bit of filament comes off the roll and into the tube leading into the extruder, I gently feed the new roll into the tube (making sure it goes through the guide block near the roll that holds the tubing) and put light pressure on it to make sure it stays in contact with the end of the previous roll until I feel the extruder motor grab the new filament. I haven't had any problems yet doing it this way.

Re: How do you deal with the end of a filament roll?

Posted: Thu Jul 17, 2014 9:17 pm

by sprior

From this description I assume you've replaced the extruder drive with one that holds onto the bowden tube? If not you'd have to feed the new filament into the extruder drive and not just the bowden tube.

Re: How do you deal with the end of a filament roll?

Posted: Fri Jul 18, 2014 1:26 am

by jsc

Re: How do you deal with the end of a filament roll?

Posted: Fri Jul 18, 2014 2:02 am

by Tim

Jin, thanks for sharing that. What a nice solution! It looks like it needs a lot of manual intervention, but it does the job. I expect that with a few more rounds of development, it will be fully automatic. It's very tempting to sign up for an early version, though.

Re: How do you deal with the end of a filament roll?

Posted: Fri Jul 18, 2014 2:18 am

by Rich

I also like this possibility, very cool idea. I remember Jin was working on something like this.

Since we all measure our filaments prior to slicing, how important will it be to make sure that all of the filaments are within .01-.02mm of each other?

Re: How do you deal with the end of a filament roll?

Posted: Fri Jul 18, 2014 2:46 am

by markb

Very cool.

I wonder if we could make something like this with a temp controlled soldering iron.

Print the clamp out of ABS….

Re: How do you deal with the end of a filament roll?

Posted: Mon Aug 04, 2014 1:03 am

by Dale Reed

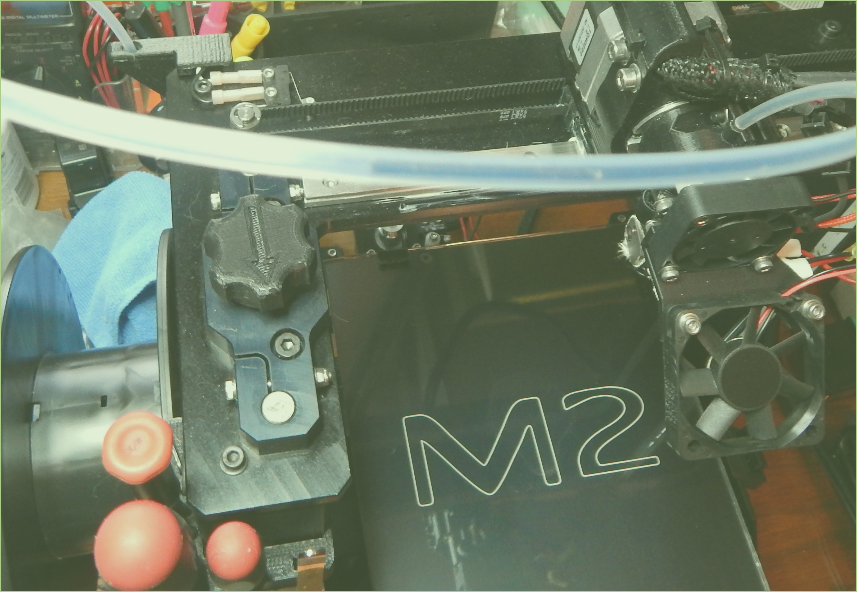

I rely on blind dumb luck. I ran a print overnight, came back to my M2 the next morning with a successful print and THIS left in the filament feed tube:

- What was left in the filament feed tube when print finished!

- WhatsLeft.png (695.6 KiB) Viewed 21665 times

Note the empty spool on the left...

Dale