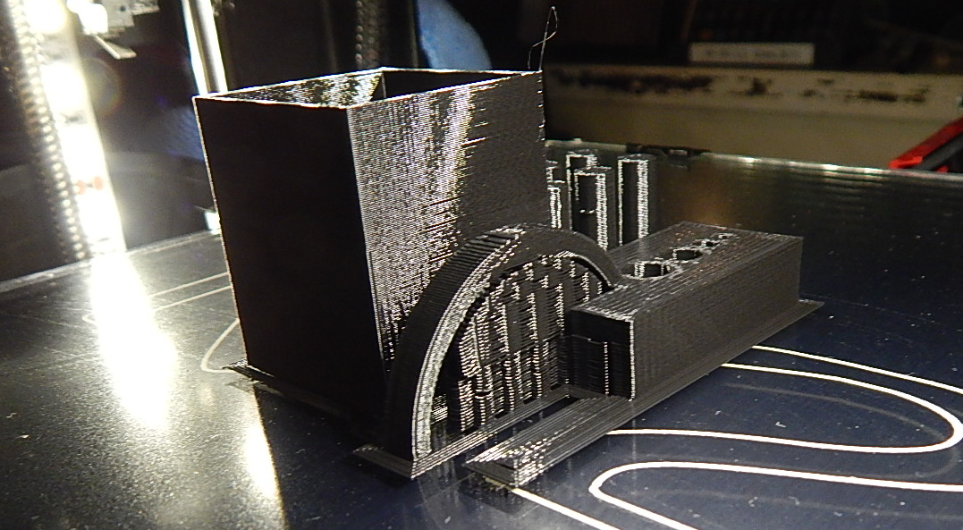

Exactly. And, yes, mine was printed with support enabled. Here it is before I removed it from the bed:

- TortureTestJustFinished.png (770.37 KiB) Viewed 17262 times

Settings:

MakerGear black PLA 1.75 mm diameter, sliced wtih Simplify3D

Extrusion temperature: 220 C (V3B hot end)

Bed temperature: 70 C

Bed prep: Aqua Net Extra Super Hold hairspray

Nozzle: 0.35 mm, extrusion multiplier 0.94

Retraction: 0.60 mm, speed 1000 mm/min, no Z lift, extra restart -0.05 mm, Coast 0.75 mm

0.20 mm layers, 2 solid bottom layers, 2 perimeters inside-->out, 3 solid top layers, optimize start points

first layer height 90%, first layer speed 50%

1 skirt layer, 0.10 mm offset, 5 outlines

50% infill at 0 and 90 degrees, no overlap, minimum 1.0 mm, every 1 layer

support infill 20% every laayer, offset 0.50 mm, 1 separation layer, resolution 1.0 mm, max overhang 45 degrees

fan 75% first layer, 100% above; reduce print speed for layers under 20 sec, down to 50%

speed 3600 mm/min, outline 75%, support 80%, rapids at 12000 mm/min, accel 2400 mm/sec^2

other: force retraction between layers, wipe for outer-most perimeters.

NOTE the infill angle -- this seemed to help quite a bit with this particular part.

And the five wraps of skirt may seem like a waste, but they really help with getting everything cleaned out and flowing nicely before starting on the part itself. With the 0.1 mm offset, it does "touch" and help a bit with adhesion, but rips off easily.

Hope this helps others...

Dale