3D Printed Chain Mail Armor

Posted: Mon Dec 08, 2014 6:04 pm

Back in my Thing-O-Matic days, I made small chain mail sheets:

http://softsolder.com/2011/06/03/thing- ... chainmail/

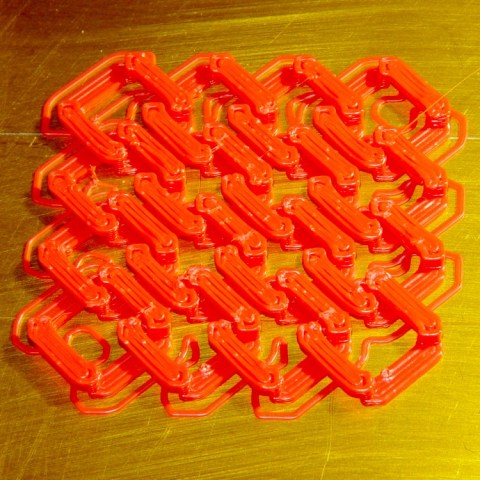

The M2's big glass plate produces bigger and much better results:

http://softsolder.com/2014/11/27/3d-pri ... ail-again/

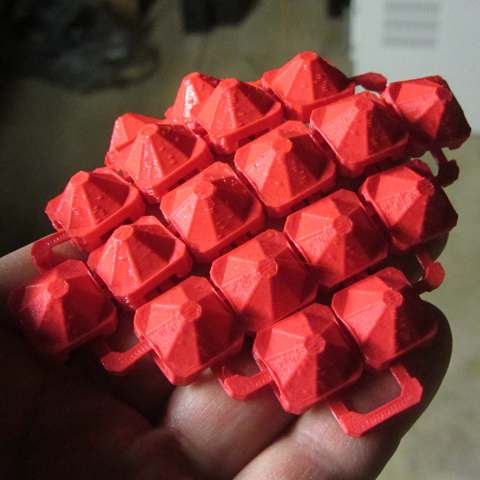

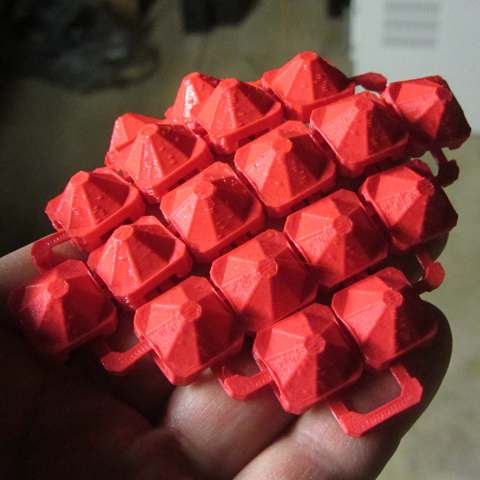

Pyramidal armor caps should repel Nerf darts:

http://softsolder.com/2014/12/04/3d-pri ... y-edition/

With armor, bigger is always better:

http://softsolder.com/2014/12/05/3d-pri ... -mm-sheet/

If that's not enough, join the sheets:

http://softsolder.com/2014/12/08/3d-pri ... ts-fabric/

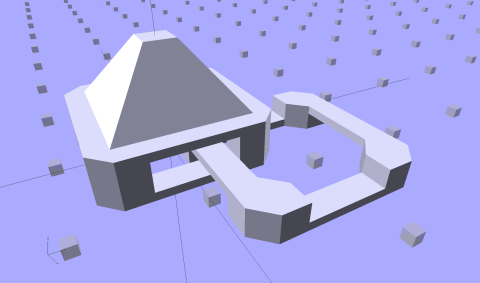

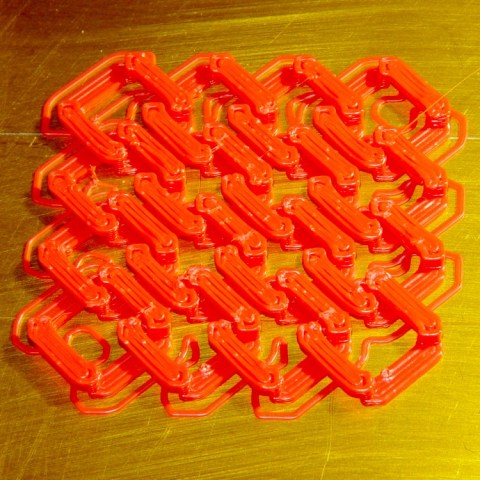

A closeup of the joint between the two big sheets, which lie left & right of the joiner links that I'm gluing in place:

The OpenSCAD program splits the joiner links horizontally under the armor cap: position the two lower bars between the sheets, apply adhesive to the four pillars, then press the cap in place. The big sheets consist of interlocked links printed as one unit that require no gluing; split links join those sheets.

The program starts with the actual extruded thread size (I'm running 0.40 mm wide x 0.20 mm thick from a 0.35 mm nozzle), then computes the link dimensions as integer multiples of the thread size to make the infill fit perfectly. That means you can't use a model built for a different printer, because the sizes won't match.

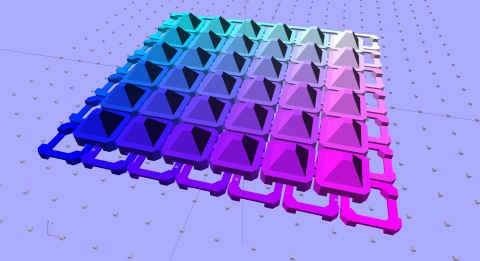

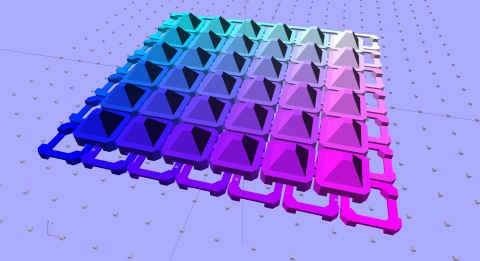

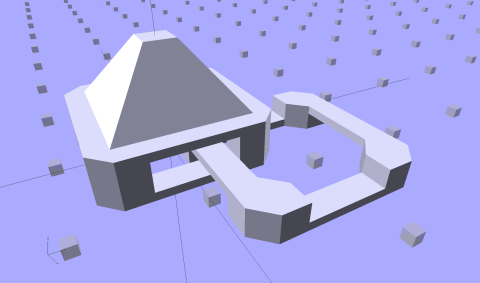

Basically, you tell the program what your printer can do and how large a sheet you want, then it builds a model to match:

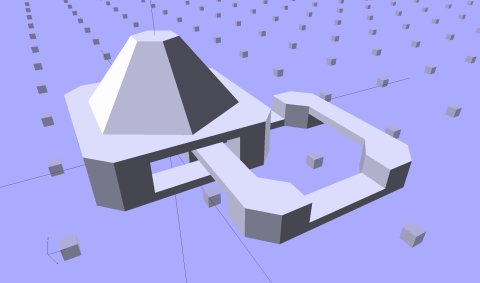

You can specify a diamond layout that rotates the links 45° with respect to the sheet sides:

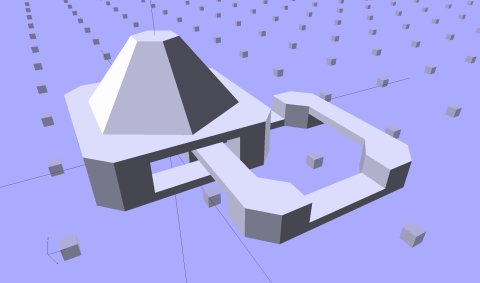

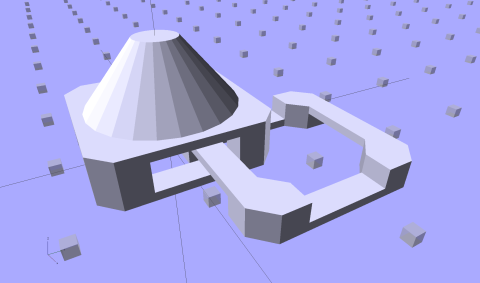

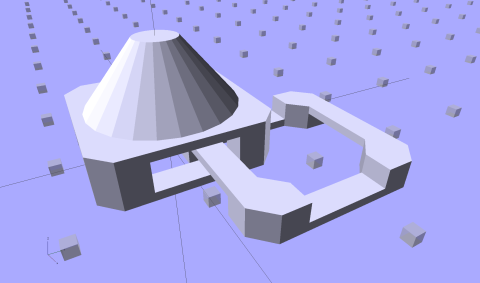

You can set the armor button shape, although I think the 4-sided pyramid looks best:

Those big sheets pose a savage test of first-layer alignment, part adhesion, and bridging performance. The 9x13 button array rises from 514 bars on the platform, stretches 748 bridges to form the links, then builds 117 flat bridges to make the armor caps. Each 9x13 sheet requires a bit over nine hours to print.

But, y'know what? All those big sheets printed without incident and came off the platform ready to use: no cleanup or post-processing at all.

The M2 Just Works...

http://softsolder.com/2011/06/03/thing- ... chainmail/

The M2's big glass plate produces bigger and much better results:

http://softsolder.com/2014/11/27/3d-pri ... ail-again/

Pyramidal armor caps should repel Nerf darts:

http://softsolder.com/2014/12/04/3d-pri ... y-edition/

With armor, bigger is always better:

http://softsolder.com/2014/12/05/3d-pri ... -mm-sheet/

If that's not enough, join the sheets:

http://softsolder.com/2014/12/08/3d-pri ... ts-fabric/

A closeup of the joint between the two big sheets, which lie left & right of the joiner links that I'm gluing in place:

The OpenSCAD program splits the joiner links horizontally under the armor cap: position the two lower bars between the sheets, apply adhesive to the four pillars, then press the cap in place. The big sheets consist of interlocked links printed as one unit that require no gluing; split links join those sheets.

The program starts with the actual extruded thread size (I'm running 0.40 mm wide x 0.20 mm thick from a 0.35 mm nozzle), then computes the link dimensions as integer multiples of the thread size to make the infill fit perfectly. That means you can't use a model built for a different printer, because the sizes won't match.

Basically, you tell the program what your printer can do and how large a sheet you want, then it builds a model to match:

You can specify a diamond layout that rotates the links 45° with respect to the sheet sides:

You can set the armor button shape, although I think the 4-sided pyramid looks best:

Those big sheets pose a savage test of first-layer alignment, part adhesion, and bridging performance. The 9x13 button array rises from 514 bars on the platform, stretches 748 bridges to form the links, then builds 117 flat bridges to make the armor caps. Each 9x13 sheet requires a bit over nine hours to print.

But, y'know what? All those big sheets printed without incident and came off the platform ready to use: no cleanup or post-processing at all.

The M2 Just Works...