Print head shifting to the right with every new layer!

Print head shifting to the right with every new layer!

Hey Gang,

Most of the time when a build goes awry, There is a clear reason. But this time, the M2 seemed to be adding + 1 to X of every layer it built, I really cant figure out if this was a glitch or error in my file, or a setup problem from my side.

The portion of the build you see here is simple enough, its got two small pads in the center of the part and a series of supports around the perimeter to support an overhang (not yet built). The problem, is that each layer seems to have shifted to the right. Then each layer above that, shifted even further. It seems on this build, my M2 was hell bent of creating a leaning tower of Pisa.

Here is a top view of the parts, notice those supports inching over with ever pass

https://www.dropbox.com/s/dip777v6oft42 ... 2.jpg?dl=0

https://www.dropbox.com/s/vf3y4xn4023rw ... 1.jpg?dl=0

Here is a front view, Its creating a nearly 1 to 1 relationship between +1Z and +1 X

https://www.dropbox.com/s/sbcutnsz3xvm1 ... 0.jpg?dl=0

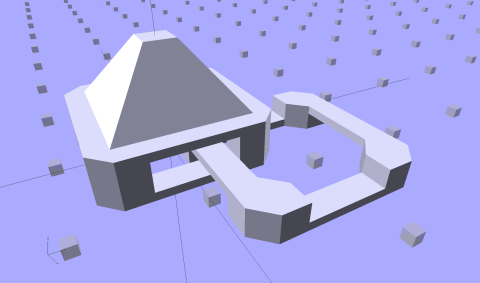

Here is a screenshot of the Build Preview

https://www.dropbox.com/s/95jh4xqxfwnp0 ... 3.png?dl=0

And Lastly, Here is a link to my Factory File and Gcode-export.

https://www.dropbox.com/sh/dcu043a6m7h4 ... 2NKQa?dl=0

PS - Table is nice and stable, not shifting at all. But even if it were loose, i cant imagine it would shift so evenly per layer.

I shut down everything and created a single instance of the file later last night and it printed okay. I really need to build multiple parts though to keep up with orders, so I'm hoping this is a bug or setting problem that I can pinpoint and squash. Any help is appreciated!!

Most of the time when a build goes awry, There is a clear reason. But this time, the M2 seemed to be adding + 1 to X of every layer it built, I really cant figure out if this was a glitch or error in my file, or a setup problem from my side.

The portion of the build you see here is simple enough, its got two small pads in the center of the part and a series of supports around the perimeter to support an overhang (not yet built). The problem, is that each layer seems to have shifted to the right. Then each layer above that, shifted even further. It seems on this build, my M2 was hell bent of creating a leaning tower of Pisa.

Here is a top view of the parts, notice those supports inching over with ever pass

https://www.dropbox.com/s/dip777v6oft42 ... 2.jpg?dl=0

https://www.dropbox.com/s/vf3y4xn4023rw ... 1.jpg?dl=0

Here is a front view, Its creating a nearly 1 to 1 relationship between +1Z and +1 X

https://www.dropbox.com/s/sbcutnsz3xvm1 ... 0.jpg?dl=0

Here is a screenshot of the Build Preview

https://www.dropbox.com/s/95jh4xqxfwnp0 ... 3.png?dl=0

And Lastly, Here is a link to my Factory File and Gcode-export.

https://www.dropbox.com/sh/dcu043a6m7h4 ... 2NKQa?dl=0

PS - Table is nice and stable, not shifting at all. But even if it were loose, i cant imagine it would shift so evenly per layer.

I shut down everything and created a single instance of the file later last night and it printed okay. I really need to build multiple parts though to keep up with orders, so I'm hoping this is a bug or setting problem that I can pinpoint and squash. Any help is appreciated!!

Last edited by BigBadBry on Mon Feb 23, 2015 5:06 pm, edited 1 time in total.

Re: Print head shifting to the right with every new layer!

That suggests two possibilities:BigBadBry wrote:created a single instance of the file later last night and it printed okay.

- The nozzle snags one of the zillion wafer-thin support structures

- The X axis acceleration is too high for all those parallel X-axis rapids

Snagging is harder to fix, particularly with auto-generated support. Watch carefully to see if the sharp corners of those thin walls curl upward as the plastic cools; that's where the nozzle will snag on the next layer. The curl gets worse as the walls get higher, eventually producing a shap cusp at the corners.

A single object can print correctly because the nozzle doesn't travel over as much cooled plastic: that's a good test to separate printer problems from model problems!

Re: Print head shifting to the right with every new layer!

Hah! I'm guessing youve shared my frustration at one time or another... Several of the corners did begin to peel up and I could hear the head bumping over them. But I figured that to be a result, not a cause tho since the corners that were kicking up were hanging out over nothing thanks to that shift in x+.

So I'm still getting familiar with things here....

When the head gets a bump, does it lose its registration pretty easy?

The corner that was coming up wasnt losing its grip on the table, it was warping on its own... What causes that? More important, how do i prevent it?

Here is a close up

Https://www.dropbox.com/s/6uuwd9u5gfpth ... 1.jpg?dl=0

On the head speed... Where tabs /setting do i adjust to make that adjustment?

So I'm still getting familiar with things here....

When the head gets a bump, does it lose its registration pretty easy?

The corner that was coming up wasnt losing its grip on the table, it was warping on its own... What causes that? More important, how do i prevent it?

Here is a close up

Https://www.dropbox.com/s/6uuwd9u5gfpth ... 1.jpg?dl=0

On the head speed... Where tabs /setting do i adjust to make that adjustment?

Re: Print head shifting to the right with every new layer!

You're right about the curling being worse for overhangs, but the repetitive nature of those layers means that after one corner snags the nozzle, it'll happen again at the same spot. As the offset increases, all the corners will be in play.BigBadBry wrote:I could hear the head bumping over them

The amount of force required to stall a stepper depends on a bunch of imponderables, but the worst case is an abrupt, non-springy impact. That's what happens when the tip of the nozzle whacks a chunk of solid plastic that's well-anchored to the platform.

The plastic thread contracts slightly as it cools, so the top layer at the tip of a right-angle corner has two "ropes" pulling it inward. The layer below is solid, the top layer is still gummy, so the tip stretches upward. The next layer atop that one starts from a slightly higher level and the pile gets higher with each additional layer.warping on its own

It's worse for single-thread walls, exactly like those support structures, because there's no infill to resist the inward tension. Solid corners won't pull up nearly as much, although as the corner angle becomes more acute, the inward force on the tip of the corner gets stronger: sharp corners distort more than shallow corners.

Back when I was using a Thing-O-Matic, Emmett's Heart Gears failed exactly that way:

http://softsolder.com/2011/06/01/thing- ... ears-fail/

The S3D users can help you with that, but it'll be called something like Travel Speed or Non-Printing Speed or some such. Find the one that says 300 mm/s or 18000 mm/min and you've got it.On the head speed... Where tabs /setting do i adjust to make that adjustment?

But that won't help with the snagging, which is what seems to be happening here.

Can you re-orient the fins so they don't need so much support? Perhaps split-and-glue two halves?

That just never stops... [grin]still getting familiar with things

Re: Print head shifting to the right with every new layer!

Thanks for the explanation (and the scary example picture, that had to be heartbreaking, lol)

So I guess I am confused about cooling PLA

Having a hot bed on one side of the part, and a cooling fan on the other seems like were just begging it to warp. Wouldn't it be better to leave the fan off?

Also, so is it safe to say that once I see an edge or comer starting to warp upward, I should kill the print rather than hope the part will right itself?

So I guess I am confused about cooling PLA

Having a hot bed on one side of the part, and a cooling fan on the other seems like were just begging it to warp. Wouldn't it be better to leave the fan off?

Also, so is it safe to say that once I see an edge or comer starting to warp upward, I should kill the print rather than hope the part will right itself?

Re: Print head shifting to the right with every new layer!

Keep the heated bed fairly cool (I run mine at 57C, cooler than S3D's stock 70C). It's used for adhesion only, you can go with blue painters tape and no heat if you're OK scraping the part off later. Use 3M 2090 tape (look inside the cardboard), it's the most common one at the hardware store that's blue. PLA sticks right to it.BigBadBry wrote:Thanks for the explanation (and the scary example picture, that had to be heartbreaking, lol)

So I guess I am confused about cooling PLA

Having a hot bed on one side of the part, and a cooling fan on the other seems like were just begging it to warp. Wouldn't it be better to leave the fan off?

Also, so is it safe to say that once I see an edge or comer starting to warp upward, I should kill the print rather than hope the part will right itself?

I'm going to guess you're missing Z-hop, which is named something silly like "retraction Z move" in S3D. This lifts the nozzle above the print when it jumps to the new spot.

Custom 3D printing for you or your business -- quote [at] pingring.org

Re: Print head shifting to the right with every new layer!

With PLA, warping is not such a big problem, and the fan helps address the overhang curling that Ed talked about. Best to leave it on.

In fact, with PLA, if you are having adhesion problems, I would start out fixing those first. You didn't say what your bed prep was. After your first few successful prints, you will either need to wash your glass with dishwashing detergent religiously, or use some sort of adhesive aid. What, if anything, are you using? I like glue stick because it is easy to apply, washes off with water, and works very well for PLA.

In fact, with PLA, if you are having adhesion problems, I would start out fixing those first. You didn't say what your bed prep was. After your first few successful prints, you will either need to wash your glass with dishwashing detergent religiously, or use some sort of adhesive aid. What, if anything, are you using? I like glue stick because it is easy to apply, washes off with water, and works very well for PLA.

Re: Print head shifting to the right with every new layer!

Z-hop? That seems like a very smart thing to have enabled. where can I find that?

IL also try dialing back that bed temp (minimize the delta T); good tips!

As far as Bed prep, I've been using the Suave Mega Hold (big pink can sold at target). I tried blue tape but it was an off-brand with a waxy finish and it didnt work well at all. Il probably pick up the tape mentioned above since its already "proven" and give that another go.

Again though, the parts that were flexing upward and snagging the tip did NOT lose adhesion to the bed, they stuck nicely with a 6-loop brim and 0 offset on hairspray (4 coats)

So in terms of "best practices"..., is it generally a bad idea to make an array of so many parts on the table for a single print (because too much time passes between layers)?

IL also try dialing back that bed temp (minimize the delta T); good tips!

As far as Bed prep, I've been using the Suave Mega Hold (big pink can sold at target). I tried blue tape but it was an off-brand with a waxy finish and it didnt work well at all. Il probably pick up the tape mentioned above since its already "proven" and give that another go.

Again though, the parts that were flexing upward and snagging the tip did NOT lose adhesion to the bed, they stuck nicely with a 6-loop brim and 0 offset on hairspray (4 coats)

So in terms of "best practices"..., is it generally a bad idea to make an array of so many parts on the table for a single print (because too much time passes between layers)?

Re: Print head shifting to the right with every new layer!

That depends entirely on what you're building. This chain mail sheet has 117 buttons and 140 connecting links that built perfectly in one operation:BigBadBry wrote:a bad idea to make an array of so many parts

http://softsolder.com/2014/12/05/3d-pri ... -mm-sheet/

The links have chamfered corners and blocky pillars with no acute angles:

They're also printed infill-first, laying the outer perimeter thread against a buttress to resist the inward tension.

So, by and large, you may find yourself printing one really tricky object all by itself to make the answer come out right, then running off dozens of easy ones in a single pass.

I've reached in with a small spatula and mashed the offending corner flat. Occasionally, that even works!kill the print rather than hope

Re: Print head shifting to the right with every new layer!

Regarding PLA and overhang curling, PLA is known for that. I haven't had a chance to look at your model and see if it would be susceptible; I'll take a look when I'm back at my computer. However, one thing I have found helps the issue is to add MORE cooling, not less. If you have an extra fan, even a desk fan, try pointing it at your model, especially the rear of the model which does not get as much benefit from the front cooling fan. It can cut down on overhang curling dramatically.

"Z-hop" is something like "lift on retract" in the Extruder tab, I believe. Set it to whatever value will get over the amount of curling you're getting. I normally use it only to prevent the nozzle from dragging over an exterior top surface and leaving a mark, for which 0.1mm is sufficient, but you may need more.

I would also try Ed's suggestion about reducing travel speed, perhaps it's skipping during travel. When's the last time you lubricated your rails?

"Z-hop" is something like "lift on retract" in the Extruder tab, I believe. Set it to whatever value will get over the amount of curling you're getting. I normally use it only to prevent the nozzle from dragging over an exterior top surface and leaving a mark, for which 0.1mm is sufficient, but you may need more.

I would also try Ed's suggestion about reducing travel speed, perhaps it's skipping during travel. When's the last time you lubricated your rails?