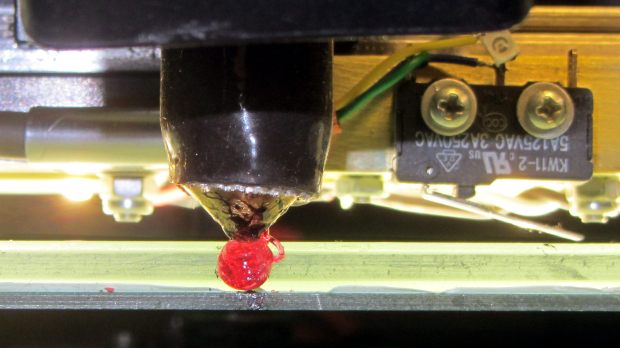

For my application the appearance of the bottom (what's printed on the platen) is important. Any unintended blobs or charred detritus makes the print unusable.

A further problem is I'm using a 0.5 mm nozzle to reduce print time and improve the clarity of the print. Larger nozzles tend to drool/ooze more.

If I sit here while the print it starting up and perform booger control, I can usually get a good result. But that's time consuming. I'd rather be able to hit the start button, go have dinner, come back and take the piece off, hit the start button again and leave.

Things I've done so far:

- I've tried retracting the filament at the end of the print as a means of reducing the drool.

I've changed the startup code such that the HBP comes up to temp before I turn on the extruder heater. That way as soon as the extruder comes up to temp it goes. Minimizing drool time.

I could increase the number of skirt loops, but that's a statistics game that I will sometimes lose.

Anybody have any other ideas??

Thanks.

bignordique