We are working on an improvement to the HBP wiring. We are considering fastening a card edge connector to the bottom rear edge of the HBP. Then the harness will just connect directly to the edge connector. I am just checking to see if you have any ideas or suggestions on this topic.

Thanks,

Rick

HBP Wiring

Re: HBP Wiring

The flying cable from chassis to HBP must have strain relief on the outboard side of the new connector, which I think puts way too much stress on the back end of the spring-supported HBP: dynamic forces applied to the the HBP change the platform Z position as a function of travel along the Y axis. Those platform springs are the weakest point of the whole design.rpollack wrote:fastening a card edge connector to the bottom rear edge of the HBP.

I'd much rather see a pigtail from the HBP to a connector mounted firmly on the Y-axis slide (below the springs), so that the pigtail doesn't move in relation to the HBP. Then you can do a good job of strain relief on the flying cable-to-connector joint, without affecting the HBP.

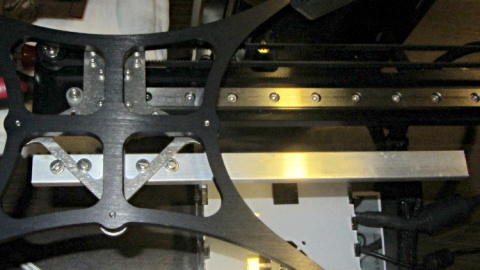

I ran a strut out the back of the Y-axis stage in a truly hideous hack:

http://softsolder.com/2013/07/05/makerg ... ilization/

Then lashed the HBP cable to that strut:

That's not as good as a pigtail with a firmly mounted connector, but it was a start.

I've since switched to a different HBP with longer wires running directly to the chassis that reduce the acute bending. It's not nearly as good-looking as the loom, though.

A pair of Anderson Powerpoles would be a much more reliable choice than any PCB edge connector, because the copper PCB traces will fret against the contacts after repeated mechanical motion. If you must clamp the connector together anyway, you may as well use a high-current latching connector and be done with it.

PCB-mount Powerpoles exist:

http://www.andersonpower.com/products/p ... rpole.html

But that PCB should be attached to the Y-axis slide, so it's not clear they're an advantage over ordinary Powerpoles on a pigtail.

Re: HBP Wiring

Thank you, Ed.

Re: HBP Wiring

A combination of Ed's idea with the splint, and a cable chain to make use of that nice, expensive automation cable you're using for the heated bed. The cable chain could be attached to the Z stage off to the side (so it collides with the electronics, hmm...) anchored by the Y motor and a printed/molded/metal part to hold the final bend from the chain to the HBP split steady.rpollack wrote:We are working on an improvement to the HBP wiring. We are considering fastening a card edge connector to the bottom rear edge of the HBP. Then the harness will just connect directly to the edge connector. I am just checking to see if you have any ideas or suggestions on this topic.

Thanks,

Rick

Custom 3D printing for you or your business -- quote [at] pingring.org

Re: HBP Wiring

This is what I did to safeguard my own wire connection. It might be nice to have it direct the wire more to the rear as opposed to the side, but the general approach seems to be easy to implement.. Another member posted a similar solution using a conduit clamp, which might be even more effective.

https://www.dropbox.com/s/d4k9wgrww6sts ... 0.jpg?dl=0

https://www.dropbox.com/s/d4k9wgrww6sts ... 0.jpg?dl=0

Re: HBP Wiring

Rick, I'm pretty sure you're aware of jimc's arrangement, where the wires come off toward the inboard side, rather than straight out the back. I do like the idea of cable-track for the flexing wires. Perhaps anchor it next to the Y motor somehow. I bought about a meter each of three or four sizes of black cable-track (from Amazon) and haven't gotten a chance to dink with them -- sitting in a box next to the desk with the M2. You're welcome to have some -- I can stop by the shop any day at lunchtime (except Friday this week). I can show you or Josh what I had in mind...insta wrote:A combination of Ed's idea with the splint, and a cable chain to make use of that nice, expensive automation cable you're using for the heated bed. The cable chain could be attached to the Z stage off to the side (so it collides with the electronics, hmm...) anchored by the Y motor and a printed/molded/metal part to hold the final bend from the chain to the HBP split steady.

Dale

Re: HBP Wiring

I just did a quick fix that seemed to work out for me.

On the plug I put a stiff piece of heat shrink tubing to take the stress off the solder joint.

On the Heated build platform I loosely zip tied the cable bundle to the plate clamp.

Hope this helps .

It can serve as a quick fix in the field until something new is adopted.

you could use electrical tape if you didn't have the heat shrink tubing.

On the plug I put a stiff piece of heat shrink tubing to take the stress off the solder joint.

On the Heated build platform I loosely zip tied the cable bundle to the plate clamp.

Hope this helps .

It can serve as a quick fix in the field until something new is adopted.

you could use electrical tape if you didn't have the heat shrink tubing.