http://softsolder.com/2015/06/13/victor ... n-chamber/

This model shows the plastic fittings that hold the circuit board directly over the ionization chamber's collecting electrode and raise the chamber's soldered base off the desk:

http://softsolder.com/2015/07/02/victor ... t-fixture/

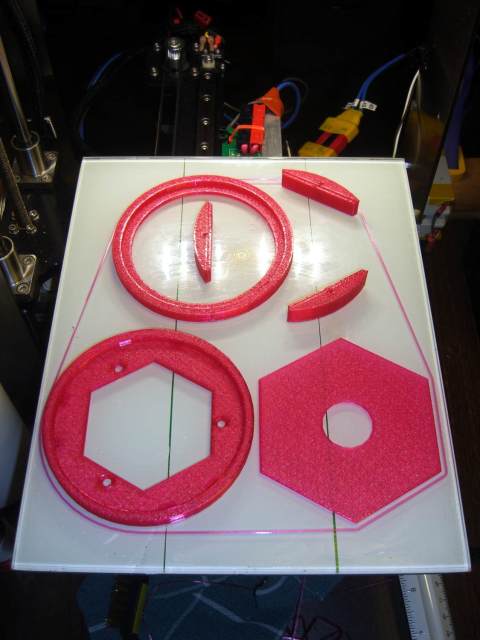

The chamber OD is 90 mm and the plastic rings adds another 5 mm on each side, so the rings measure 100 mm OD and won't quite fit side-by-side on the M2's platform. However, nesting one of the three PCB supports inside the base ring and snuggling the hexagonal circuit board template beside the cap ring works fine:

The skirt around the objects came out 0.25±0.05 mm high, without requiring any particular attention. The M2 came with me to the CNC Workshop in Detroit two weeks ago and, after a 1500 mile round trip in the back of our Forester, the platform was still aligned and the Z=0 point was off by only 0.03 mm. I loves me my M2!

The supports glue onto the cap ring, with pairs of filament snippets holding them in alignment, and the machine screw heads clamp the circuit board into the holder rabbets. The cap assembly looks like this from the top:

Slic3r's Hilbert Curve infill produces a pleasant grainy texture on top and bottom surfaces that doesn't look or feel at all like the usual linear pattern.

That's eSun magenta ("red") PETG: v4 hot end, 250 °C extruder / 90 °C platform, 75 mm/s infill, 50 mm/s perimeters, 15 mm/s first layer, 15% 3D Honeycomb infill. I reamed out the screw holes with a #36 drill, but that's the only "finishing" it required.

OK, it's not nearly as impressive as jereywolf's skulls, but it solves my problem... [grin]